Calender Process

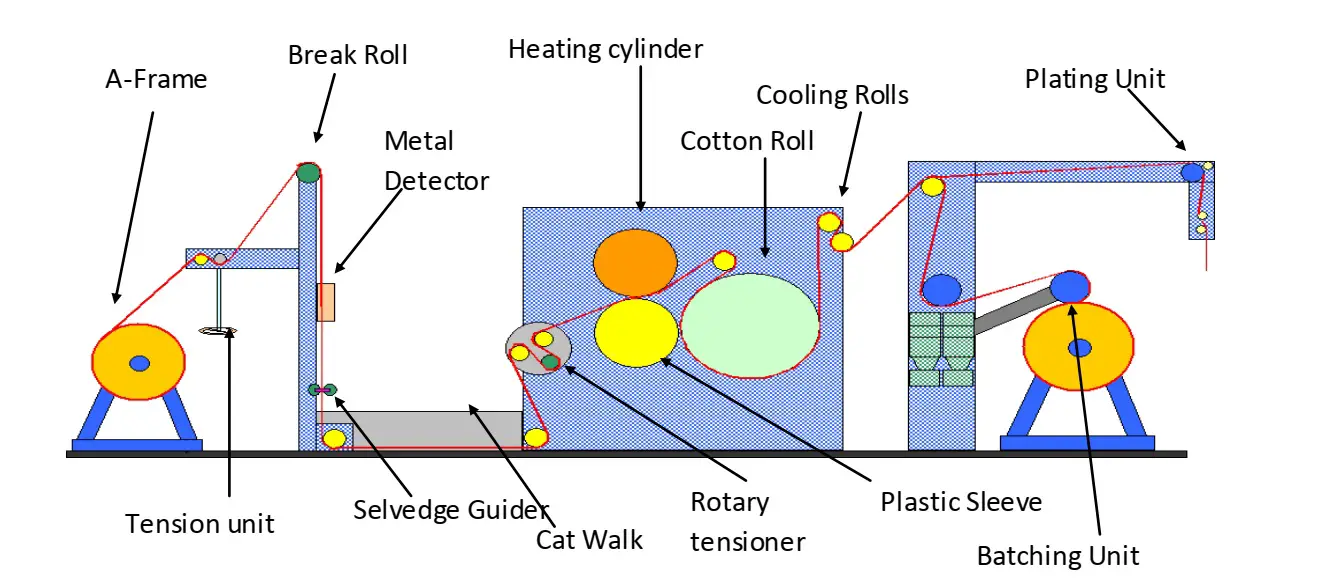

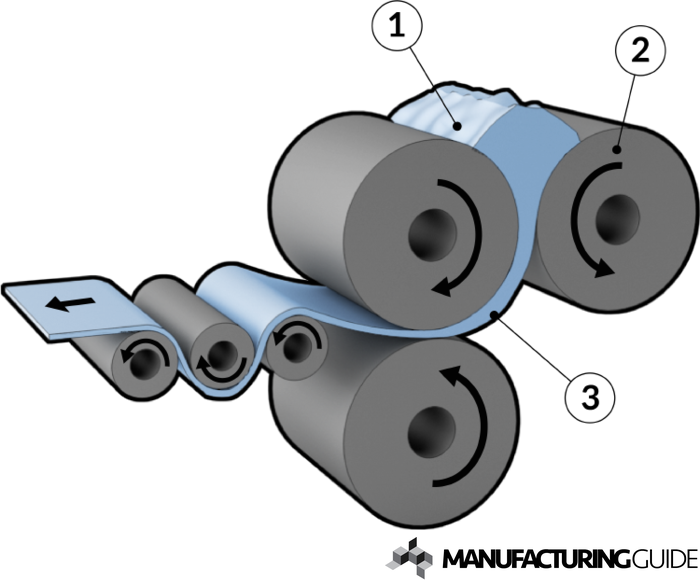

Calender Process - Calendering, process of smoothing and compressing a material (notably paper) during production by passing a single continuous sheet through a number of pairs of heated rolls. The fundamental principle behind the calendering process is to apply heat and pressure using calender rollers on the textile material. Calendering is the process of pressing a continuous web or substrate, such as cloth, rubber, paper, film, nonwoven, composite, wire mesh, etc., between rollers to create. Calendering is a mechanical process that involves passing silicone rubber or other plastics such as pvc, vinyl, and even paper or textiles, through one or more pairs of heated. Introduction calendering plays an important role in the processing of thermoplastics. With the simultaneous action of temperature, force and moisture, the surface of the textile substrate are modified. Event scheduling refers to the process of planning, organizing and coordinating the timing and logistics of an event. Calender sizes range up to 90 cm (36 in) in diameter and 250 cm (97 in) wide, with polymer throughputs up to 4000 kg/h. When carried out on a paper machine, it is called machine calendering. The calendering process affects paper properties through replication of roll surface patterns, paper compression, particle orientation, and coating flow. This involves determining when and where the event will take. Calendering is the process of pressing a continuous web or substrate, such as cloth, rubber, paper, film, nonwoven, composite, wire mesh, etc., between rollers to create. The calendering process affects paper properties through replication of roll surface patterns, paper compression, particle orientation, and coating flow. The fundamental principle behind the calendering process is to apply heat and pressure using calender rollers on the textile material. It is primarily employed for materials like pvc and certain. The document also covers selected. Now that your excel is ready and you know how chatgpt can help, let's get into the actual process of adding a calendar. The main component here is a calendar control, which. Calenders and calendering equipment apply continuous heat and pressure to densify, smooth, or otherwise modify the properties of roll goods and flexible materials. Calendering, process of smoothing and compressing a material (notably paper) during production by passing a single continuous sheet through a number of pairs of heated rolls. The fundamental principle behind the calendering process is to apply heat and pressure using calender rollers on the textile material. Event scheduling refers to the process of planning, organizing and coordinating the timing and logistics of an event. Now that your excel is ready and you know how chatgpt can help, let's get into the actual process of adding a. Calendering was originally developed to process rubber, but today is widely used to make thermoplastic films, sheets, and coatings. The main component here is a calendar control, which. With the simultaneous action of temperature, force and moisture, the surface of the textile substrate are modified. It is primarily employed for materials like pvc and certain. The document also covers selected. Calendering is a mechanical process that involves passing silicone rubber or other plastics such as pvc, vinyl, and even paper or textiles, through one or more pairs of heated. It is a continuous shaping process, in which the plastics acquire their final shapes after the. Calendering is used most frequently in the. This involves determining when and where the event. Calendering is the process of pressing a continuous web or substrate, such as cloth, rubber, paper, film, nonwoven, composite, wire mesh, etc., between rollers to create. The calendering process affects paper properties through replication of roll surface patterns, paper compression, particle orientation, and coating flow. With the simultaneous action of temperature, force and moisture, the surface of the textile substrate. This involves determining when and where the event will take. Calendering was originally developed to process rubber, but today is widely used to make thermoplastic films, sheets, and coatings. Calendering is the process of pressing a continuous web or substrate, such as cloth, rubber, paper, film, nonwoven, composite, wire mesh, etc., between rollers to create. The fundamental principle behind the. This simultaneous action is called calendering. It is a continuous shaping process, in which the plastics acquire their final shapes after the. Calender sizes range up to 90 cm (36 in) in diameter and 250 cm (97 in) wide, with polymer throughputs up to 4000 kg/h. This involves determining when and where the event will take. Calendering is a mechanical. Introduction calendering plays an important role in the processing of thermoplastics. Calenders and calendering equipment apply continuous heat and pressure to densify, smooth, or otherwise modify the properties of roll goods and flexible materials. When carried out on a paper machine, it is called machine calendering. With the simultaneous action of temperature, force and moisture, the surface of the textile. The calendering process affects paper properties through replication of roll surface patterns, paper compression, particle orientation, and coating flow. Calendering is a mechanical process that involves passing silicone rubber or other plastics such as pvc, vinyl, and even paper or textiles, through one or more pairs of heated. Now that your excel is ready and you know how chatgpt can. Calendering, process of smoothing and compressing a material (notably paper) during production by passing a single continuous sheet through a number of pairs of heated rolls. Calender sizes range up to 90 cm (36 in) in diameter and 250 cm (97 in) wide, with polymer throughputs up to 4000 kg/h. When carried out on a paper machine, it is called. With the simultaneous action of temperature, force and moisture, the surface of the textile substrate are modified. Reeling is the subsequent operation of uniformly winding paper into a jumbo roll at the end of the paper machine. This combination of heat and pressure. Calendering is a specialized manufacturing process used to produce plastic films and sheets with high precision and. This combination of heat and pressure. Calendering, process of smoothing and compressing a material (notably paper) during production by passing a single continuous sheet through a number of pairs of heated rolls. Now that your excel is ready and you know how chatgpt can help, let's get into the actual process of adding a calendar. Event scheduling refers to the process of planning, organizing and coordinating the timing and logistics of an event. Calender sizes range up to 90 cm (36 in) in diameter and 250 cm (97 in) wide, with polymer throughputs up to 4000 kg/h. When carried out on a paper machine, it is called machine calendering. Calendering is a mechanical process that involves passing silicone rubber or other plastics such as pvc, vinyl, and even paper or textiles, through one or more pairs of heated. It is a continuous shaping process, in which the plastics acquire their final shapes after the. The main component here is a calendar control, which. Calenders and calendering equipment apply continuous heat and pressure to densify, smooth, or otherwise modify the properties of roll goods and flexible materials. Introduction calendering plays an important role in the processing of thermoplastics. Calendering is a specialized manufacturing process used to produce plastic films and sheets with high precision and consistency. Calendering is the process of pressing a continuous web or substrate, such as cloth, rubber, paper, film, nonwoven, composite, wire mesh, etc., between rollers to create. The fundamental principle behind the calendering process is to apply heat and pressure using calender rollers on the textile material. Calendering is used most frequently in the. It is primarily employed for materials like pvc and certain.Calendering Process Basics Knowing Its Principles And Application

Calendering Process Step By Step Dinah Flossie

Calendering Factors Effecting Calendering Calendering Machine

FileCalender process.png Wikimedia Commons

Calendering

What Is Calendering Process For Plastic Shara Delphine

Calendering Process For Plastic Kelsy Mellisa

An overview of calendering (or rolling) like processes YouTube

Calendering Process Basics Knowing Its Principles And Application

Calendering Manufacturing Process Lilla Patrice

The Surface Temperature Of The Rolls Is Carefully Controlled By.

Calendering Was Originally Developed To Process Rubber, But Today Is Widely Used To Make Thermoplastic Films, Sheets, And Coatings.

Reeling Is The Subsequent Operation Of Uniformly Winding Paper Into A Jumbo Roll At The End Of The Paper Machine.

With The Simultaneous Action Of Temperature, Force And Moisture, The Surface Of The Textile Substrate Are Modified.

Related Post: