Calendered Material

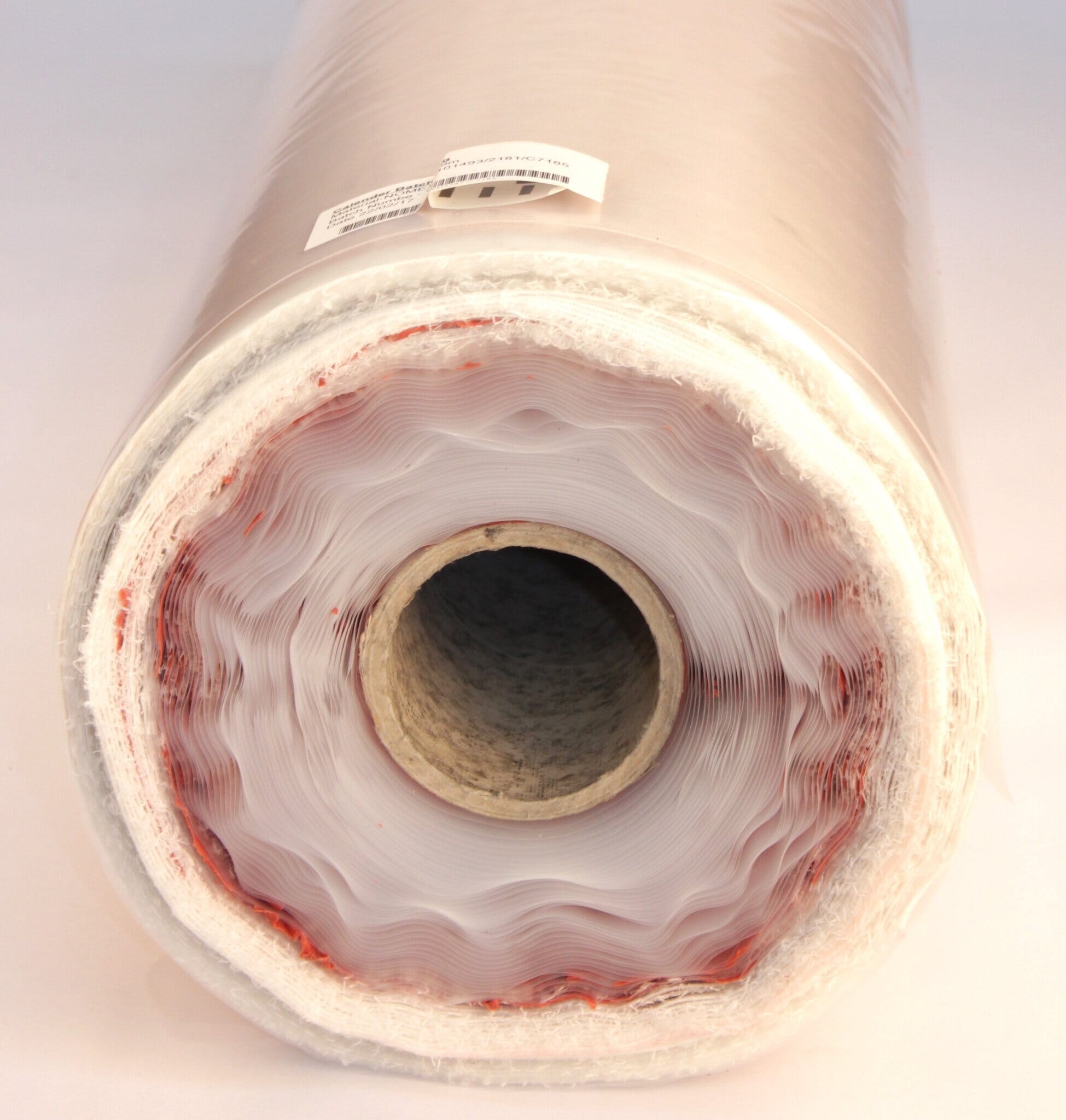

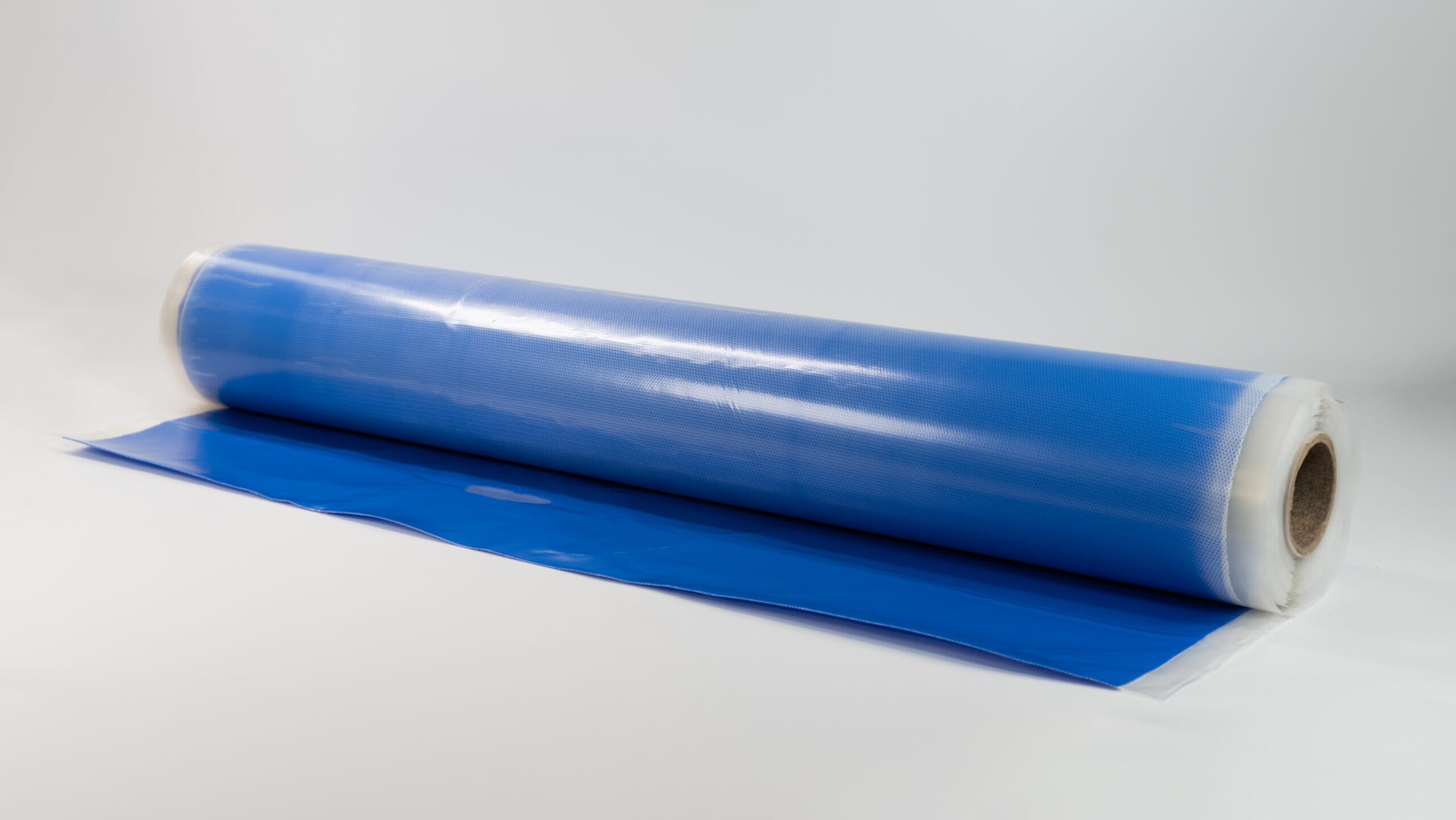

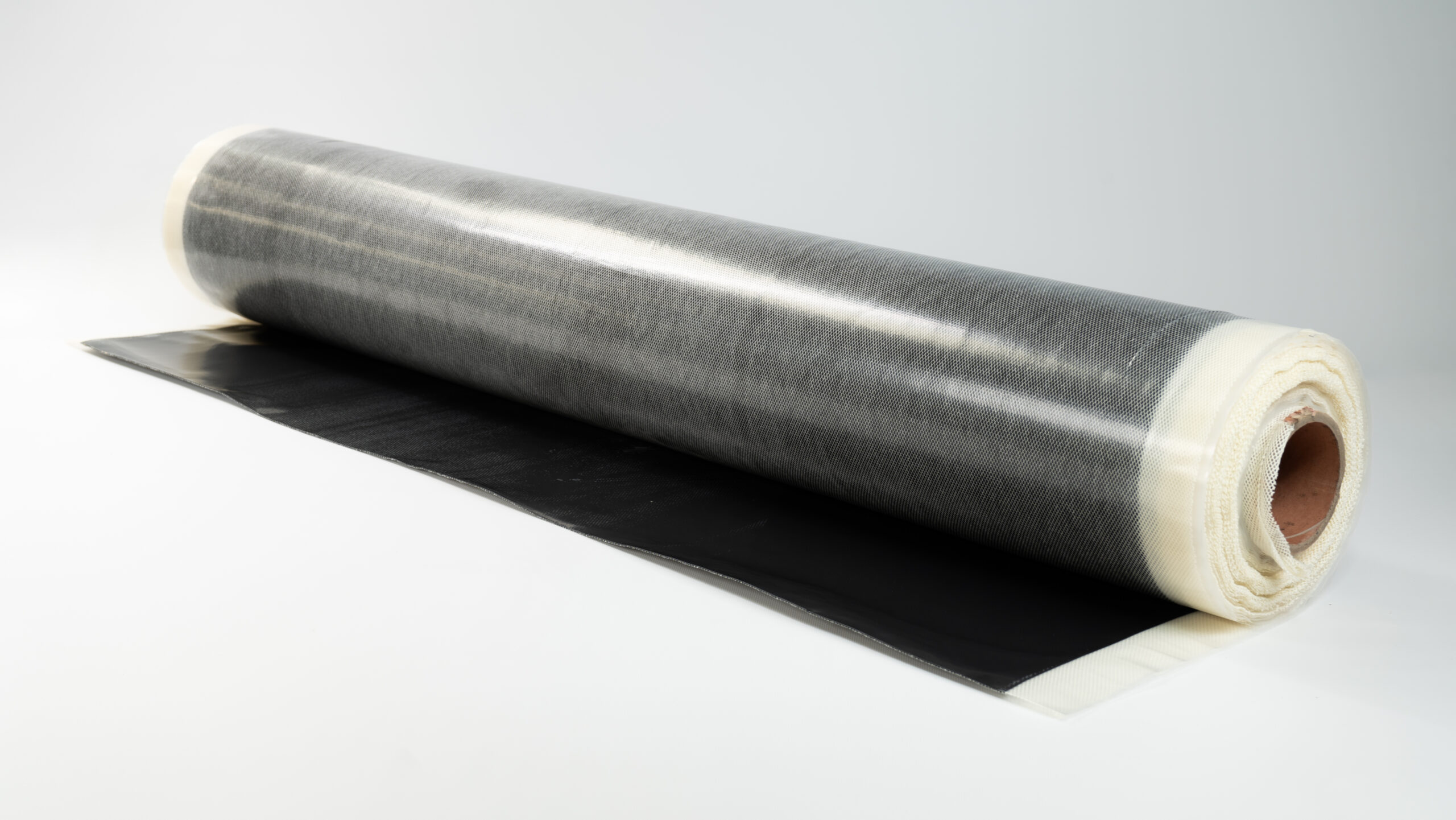

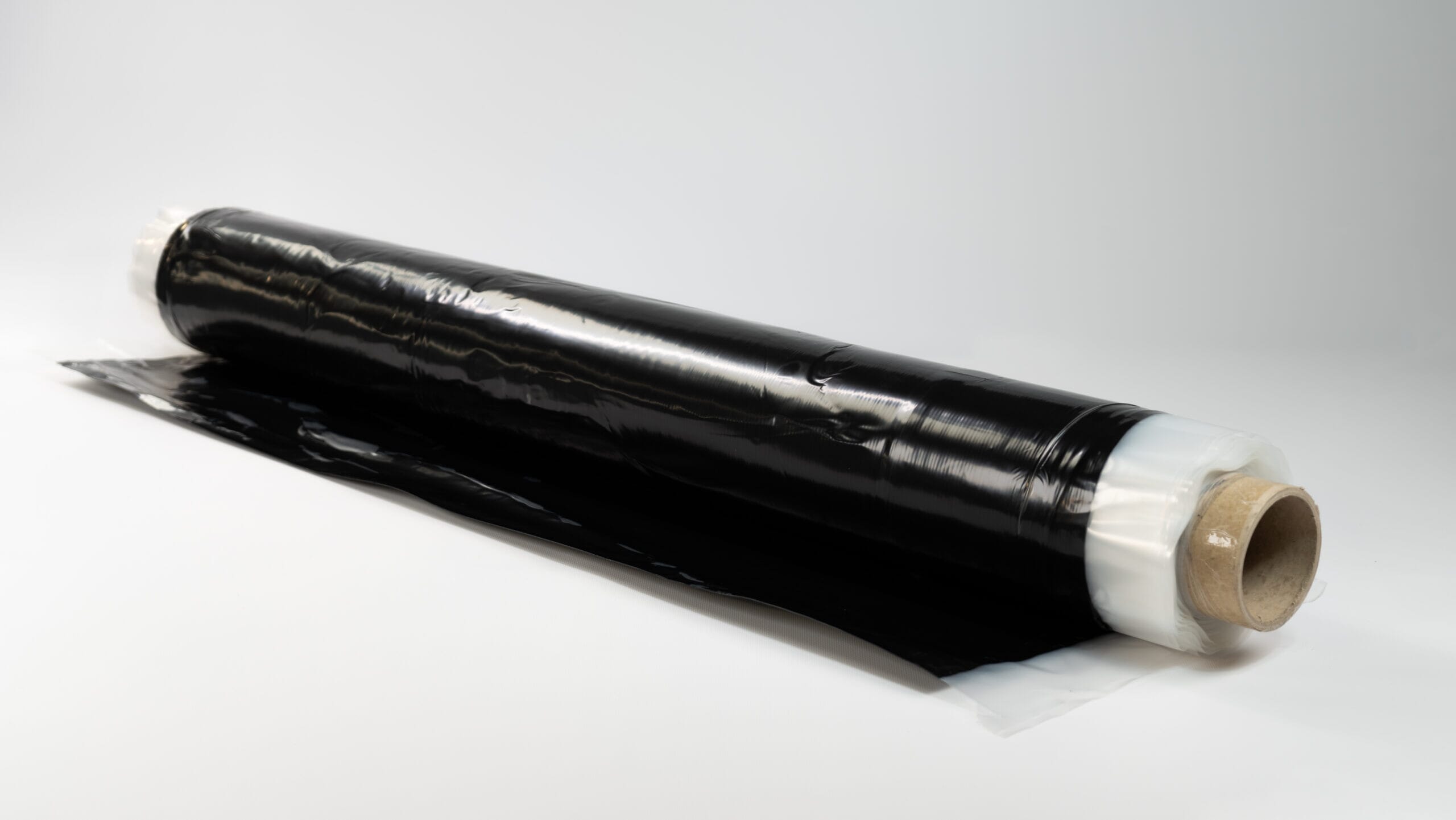

Calendered Material - This makes calendered vinyl decals perfect for flat or curved surfaces. Calendered materials offer excellent surface finishes, consistent thicknesses, and desirable physical properties, making them ideal for applications such as food packaging,. Here’s what to know about each and. Calendered vinyl is comparatively thicker and best for flat and less complex surfaces. You can use these types of materials to improve a range of camping and backpacking gear, like sleeping. The first thing people notice about calendered fabric is the way it feels. Calendered vinyl films are best for flat, simple surfaces, while cast vinyl films are more suitable for complex surfaces with curves and contours. Here are three reasons why you might want to use calendered fabrics. Calendered vinyl begins as a pvc plastic and is manufactured via calendering, which involves passing the vinyl material through heated rollers (called calenders) to apply pressure and. Calendered vinyl is a high gloss material. Calendered vinyl is thicker, heavier, less conformable, and has more dimensional stability. This makes calendered vinyl decals perfect for flat or curved surfaces. Calendered vinyl is a high gloss material. Cast vinyl is thin and flexible and excellent for curves and contours. Downproof and calendered fabrics are suitable for a variety of different diy projects. Here’s what to know about each and. Calendered vinyl is comparatively thicker and best for flat and less complex surfaces. Calendered materials offer excellent surface finishes, consistent thicknesses, and desirable physical properties, making them ideal for applications such as food packaging,. Here are three reasons why you might want to use calendered fabrics. The first thing people notice about calendered fabric is the way it feels. Calendered vinyl is comparatively thicker and best for flat and less complex surfaces. Calendered vinyl is thicker, heavier, less conformable, and has more dimensional stability. Cast vinyl is thin and flexible and excellent for curves and contours. This makes calendered vinyl decals perfect for flat or curved surfaces. Downproof and calendered fabrics are suitable for a variety of different diy. Decals printed on calendered vinyl are much easier to handle and apply than cast vinyl. Here are three reasons why you might want to use calendered fabrics. This makes calendered vinyl decals perfect for flat or curved surfaces. Calendered vinyl is thicker, heavier, less conformable, and has more dimensional stability. The first thing people notice about calendered fabric is the. The first thing people notice about calendered fabric is the way it feels. Decals printed on calendered vinyl are much easier to handle and apply than cast vinyl. Downproof and calendered fabrics are suitable for a variety of different diy projects. Calendered materials offer excellent surface finishes, consistent thicknesses, and desirable physical properties, making them ideal for applications such as. It is less costly as well. You can use these types of materials to improve a range of camping and backpacking gear, like sleeping. Calendered vinyl begins as a pvc plastic and is manufactured via calendering, which involves passing the vinyl material through heated rollers (called calenders) to apply pressure and. The lamination provides a uv protectant / scratch restistance. Here’s what to know about each and. You can use these types of materials to improve a range of camping and backpacking gear, like sleeping. The lamination provides a uv protectant / scratch restistance which protects from being scratched and fading. It is less costly as well. Calendered vinyl is a high gloss material. Calendered vinyl is comparatively thicker and best for flat and less complex surfaces. Calendered vinyl is thicker, heavier, less conformable, and has more dimensional stability. The first thing people notice about calendered fabric is the way it feels. You can use these types of materials to improve a range of camping and backpacking gear, like sleeping. This makes calendered vinyl. Calendered vinyl films are best for flat, simple surfaces, while cast vinyl films are more suitable for complex surfaces with curves and contours. You can use these types of materials to improve a range of camping and backpacking gear, like sleeping. The primary difference between calendered and uncalendered materials is that calendering results in a more polished and uniform product,. Downproof and calendered fabrics are suitable for a variety of different diy projects. This makes calendered vinyl decals perfect for flat or curved surfaces. Here’s what to know about each and. You can use these types of materials to improve a range of camping and backpacking gear, like sleeping. Cast vinyl is thin and flexible and excellent for curves and. Calendered vinyl is thicker, heavier, less conformable, and has more dimensional stability. The lamination provides a uv protectant / scratch restistance which protects from being scratched and fading. Downproof and calendered fabrics are suitable for a variety of different diy projects. Calendering, process of smoothing and compressing a material (notably paper) during production by passing a single continuous sheet through. Calendered vinyl is comparatively thicker and best for flat and less complex surfaces. Calendered vinyl is thicker, heavier, less conformable, and has more dimensional stability. Here are three reasons why you might want to use calendered fabrics. Downproof and calendered fabrics are suitable for a variety of different diy projects. Here’s what to know about each and. The first thing people notice about calendered fabric is the way it feels. You can use these types of materials to improve a range of camping and backpacking gear, like sleeping. Downproof and calendered fabrics are suitable for a variety of different diy projects. This makes calendered vinyl decals perfect for flat or curved surfaces. Calendering, process of smoothing and compressing a material (notably paper) during production by passing a single continuous sheet through a number of pairs of heated rolls. Calendered vinyl begins as a pvc plastic and is manufactured via calendering, which involves passing the vinyl material through heated rollers (called calenders) to apply pressure and. Here are three reasons why you might want to use calendered fabrics. The primary difference between calendered and uncalendered materials is that calendering results in a more polished and uniform product, while uncalendered materials tend. It is less costly as well. The lamination provides a uv protectant / scratch restistance which protects from being scratched and fading. Calendered vinyl is thicker, heavier, less conformable, and has more dimensional stability. Here’s what to know about each and. Calendered vinyl is a high gloss material. Calendered materials offer excellent surface finishes, consistent thicknesses, and desirable physical properties, making them ideal for applications such as food packaging,.Silicone Standard Calendered Material Standard Metaaramid Goodflex

Silicone Platinum Calendered Material Food Grade Goodflex Rubber

Silicone Standard Calendered Material Standard Metaaramid Goodflex

Silicone Fire Retardant Calendered Material Fire Retardant Goodflex

Silicone Standard Calendered Material Standard Polyester Goodflex

Silicone Calendered Material High Temperature THT Glass Goodflex Rubber

Solid calendered sheet and coil material Siparts

Cast vs Calendered PSV Indy Imaging Inc.

Calendered Silicone Material Antistatic Goodflex Rubber

Calendered Silicone Material Goodflex Rubber

Calendered Vinyl Is Comparatively Thicker And Best For Flat And Less Complex Surfaces.

Cast Vinyl Is Thin And Flexible And Excellent For Curves And Contours.

Calendered Vinyl Films Are Best For Flat, Simple Surfaces, While Cast Vinyl Films Are More Suitable For Complex Surfaces With Curves And Contours.

Decals Printed On Calendered Vinyl Are Much Easier To Handle And Apply Than Cast Vinyl.

Related Post: