Calendering Of Fabric

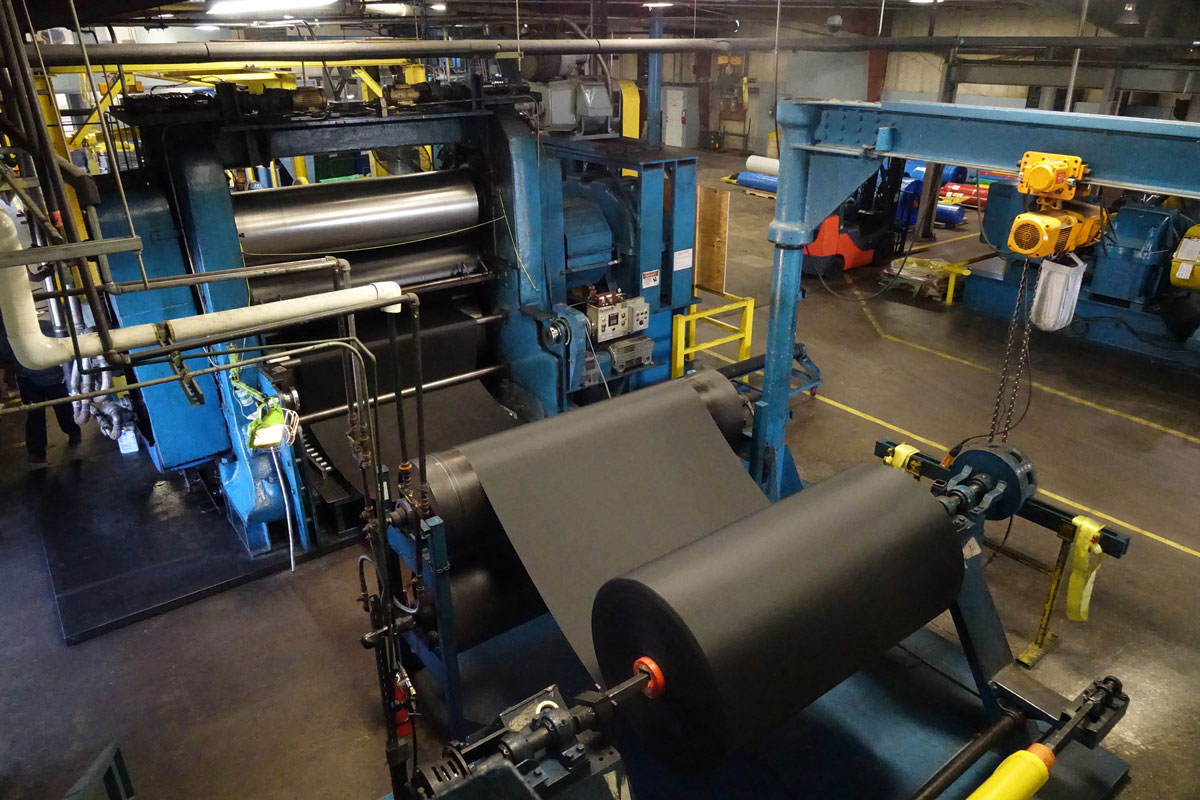

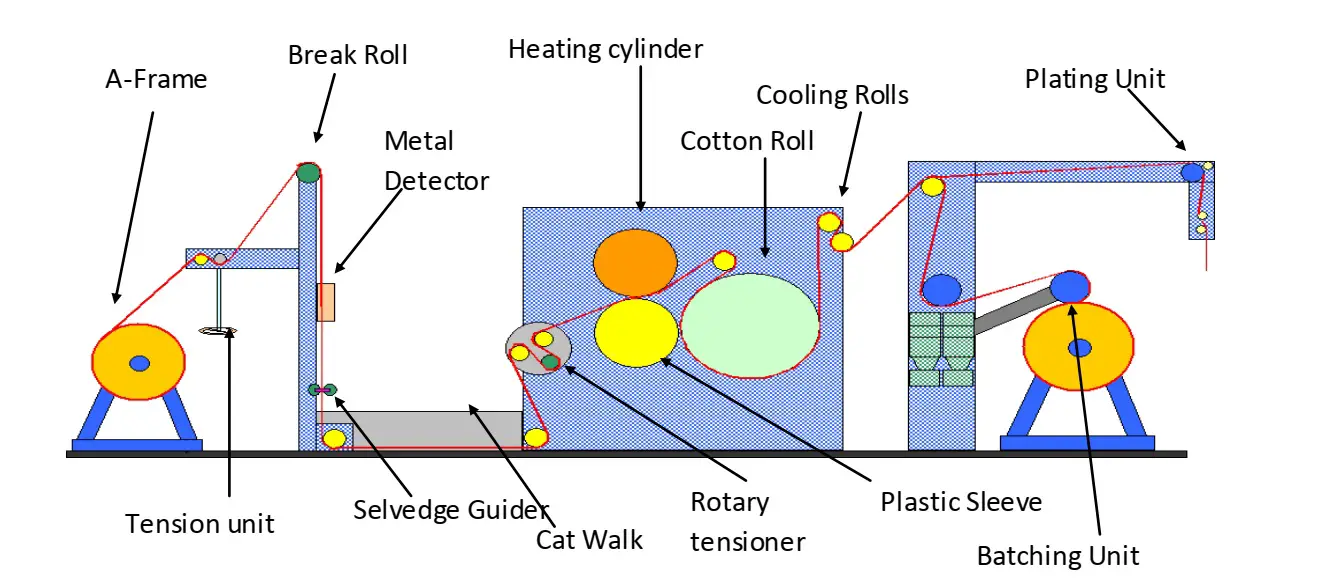

Calendering Of Fabric - Calendering enhances fabric smoothness and luster, improving its appearance and texture. This finishing process involves passing fabric. Understanding the best fabric for calendering is crucial for achieving the desired finish, whether you're working with cotton, polyester, or blends. Calendering is a process used to upgrade fabric handle and impart a smooth, silky touch. Lay the fabric on a flat surface like a table. Start by laying the fabric out just like it came off of the bolt, with the selvages together. Calendering is a critical finishing technique in textile engineering that dramatically enhances the look, texture, and overall performance of fabrics. Calendering imparts a glossy finish to cotton fabrics, enhancing their lustre and giving them a more polished appearance. Calendering is a mechanical finishing process that involves passing fabric through a series of heated rollers under high pressure. Calendering is a crucial process in textile and rubber manufacturing, primarily aimed at enhancing the surface properties, appearance, and handling of materials. With the simultaneous action of temperature, force and moisture, the surface of the textile substrate are modified. To fulfill this object cotton, linen, rayon, silk materials are applied a temporary physical finish which is known as calendaring. Calendering is a critical finishing technique in textile engineering that dramatically enhances the look, texture, and overall performance of fabrics. Start by laying the fabric out just like it came off of the bolt, with the selvages together. Calendering is a mechanical finishing process used on cloth where fabric is folded in half and passed under rollers at high temperatures and pressures. Calendering is a crucial process in textile and rubber manufacturing, primarily aimed at enhancing the surface properties, appearance, and handling of materials. Calendaring is used on fabrics such as moiré to produce its watered effect and also on cambric and some types of sateen's. The first thing people notice about calendered fabric is the way it feels. Here are three reasons why you might want to use calendered fabrics. Calendering is a mechanical finishing process that involves passing fabric through a series of heated rollers under high pressure. Lay the fabric on a flat surface like a table. In this process fabric is passed through a series. Calendaring is used on fabrics such as moiré to produce its watered effect and also on cambric and some types of sateen's. Calendering imparts a glossy finish to cotton fabrics, enhancing their lustre and giving them a more polished appearance. Calendering. Start by laying the fabric out just like it came off of the bolt, with the selvages together. The first thing people notice about calendered fabric is the way it feels. Calendering is a critical finishing technique in textile engineering that dramatically enhances the look, texture, and overall performance of fabrics. In this process fabric is passed through a series.. This can elevate the aesthetic appeal of the fabric, making them. Calendaring is used on fabrics such as moiré to produce its watered effect and also on cambric and some types of sateen's. This finishing process involves passing fabric. Calendering is a mechanical finishing process that involves passing fabric through a series of heated rollers under high pressure. Here are. The first thing people notice about calendered fabric is the way it feels. Calendering is a mechanical finishing process that involves passing fabric through a series of heated rollers under high pressure. Here are three reasons why you might want to use calendered fabrics. This can elevate the aesthetic appeal of the fabric, making them. Calendering is a mechanical finishing. With the simultaneous action of temperature, force and moisture, the surface of the textile substrate are modified. Calendering enhances fabric smoothness and luster, improving its appearance and texture. This finishing process involves passing fabric. To fulfill this object cotton, linen, rayon, silk materials are applied a temporary physical finish which is known as calendaring. Understanding the best fabric for calendering. Calendering is a critical finishing technique in textile engineering that dramatically enhances the look, texture, and overall performance of fabrics. Here are three reasons why you might want to use calendered fabrics. It involves passing fabric or. This simultaneous action is called calendering. In this process fabric is passed through a series. The process can enhance the luster,. Here are three reasons why you might want to use calendered fabrics. Understanding the best fabric for calendering is crucial for achieving the desired finish, whether you're working with cotton, polyester, or blends. There are several types of calenders that produce different effects. Factors such as fiber content,. Calendering enhances fabric smoothness and luster, improving its appearance and texture. Factors such as fiber content,. Calendering is a mechanical finishing process used on cloth where fabric is folded in half and passed under rollers at high temperatures and pressures. The primary purpose is to alter the fabric's surface. This can elevate the aesthetic appeal of the fabric, making them. This can elevate the aesthetic appeal of the fabric, making them. Calendering increases fabric density and compacts fibers, resulting in improved fabric. This finishing process involves passing fabric. There are several types of calenders that produce different effects. Next, fold down the selvage edges to just. Calendering is a mechanical finishing process that involves passing fabric through a series of heated rollers under high pressure. Calendering is a process used to upgrade fabric handle and impart a smooth, silky touch. Lay the fabric on a flat surface like a table. In this process fabric is passed through a series. Calendering is a critical finishing technique in. The process can enhance the luster,. Calendering imparts a glossy finish to cotton fabrics, enhancing their lustre and giving them a more polished appearance. Here are three reasons why you might want to use calendered fabrics. Start by laying the fabric out just like it came off of the bolt, with the selvages together. Calendering is a crucial process in textile and rubber manufacturing, primarily aimed at enhancing the surface properties, appearance, and handling of materials. Calendering is a mechanical finishing process that involves passing fabric through a series of heated rollers under high pressure. Lay the fabric on a flat surface like a table. With the simultaneous action of temperature, force and moisture, the surface of the textile substrate are modified. Understanding the best fabric for calendering is crucial for achieving the desired finish, whether you're working with cotton, polyester, or blends. Next, fold down the selvage edges to just. This simultaneous action is called calendering. Calendering is a mechanical finishing process used on cloth where fabric is folded in half and passed under rollers at high temperatures and pressures. In this process fabric is passed through a series. The primary purpose is to alter the fabric's surface. Calendering enhances fabric smoothness and luster, improving its appearance and texture. This finishing process involves passing fabric.What is Calendering & Objective of Fabric Calender Finishing Process

Calendering process in textile

fabric Calendering process, caledar laundry, electric press machine for

CSI Calendering, Inc Textiles

Calendering Factors Effecting Calendering Calendering Machine

Fabric Calendering Process Nina Teresa

The Magic Of Calendering Process In Textile Engineering Beyond Thread

Calendering process in textile

Fabric Calendering Facilities NEHHDC

Calendering:Woven Fabric Finishing Process textilewebinfo

The First Thing People Notice About Calendered Fabric Is The Way It Feels.

There Are Several Types Of Calenders That Produce Different Effects.

Calendering Is A Process Used To Upgrade Fabric Handle And Impart A Smooth, Silky Touch.

Calendaring Is Used On Fabrics Such As Moiré To Produce Its Watered Effect And Also On Cambric And Some Types Of Sateen's.

Related Post: