Calendering Process

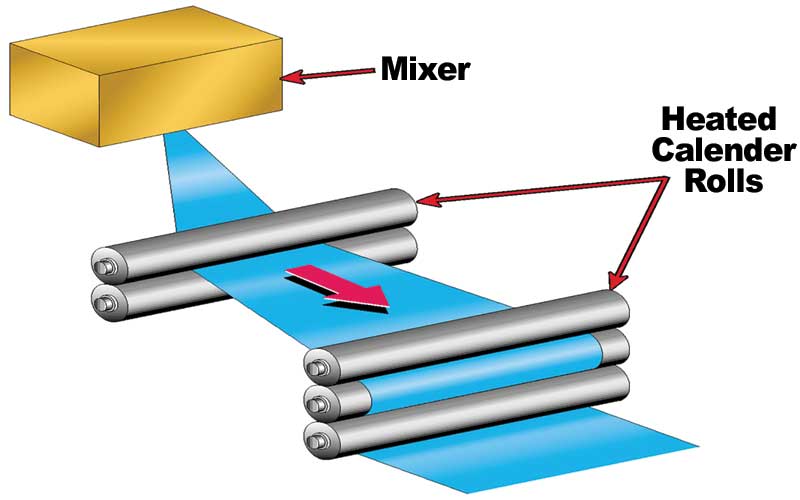

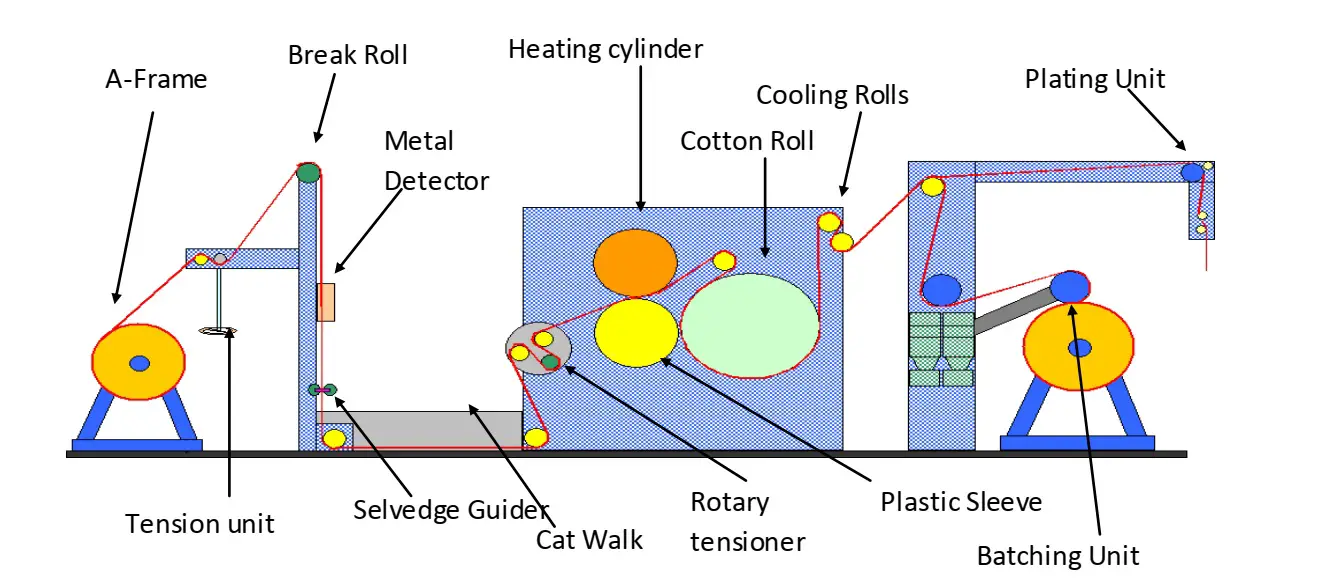

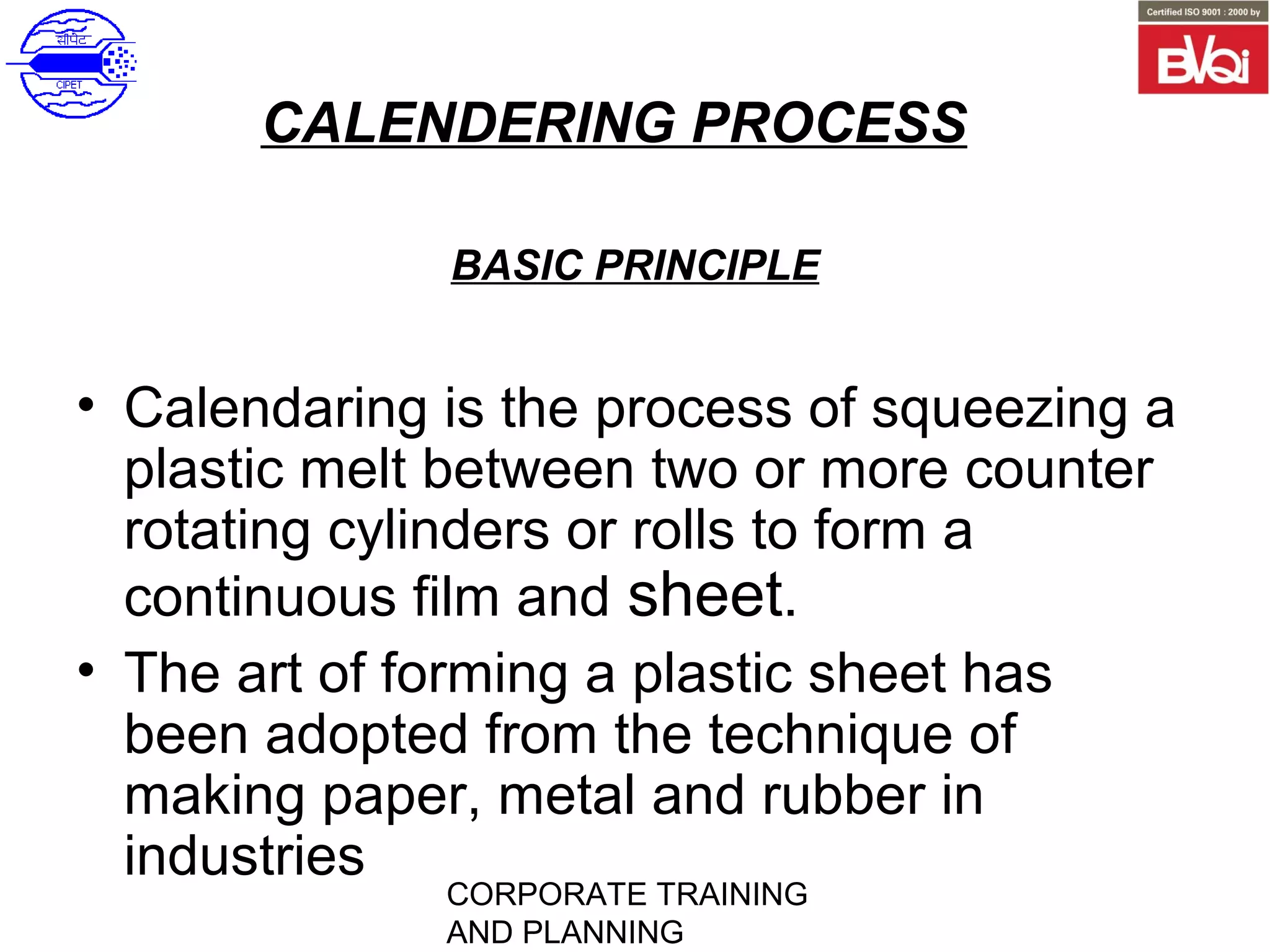

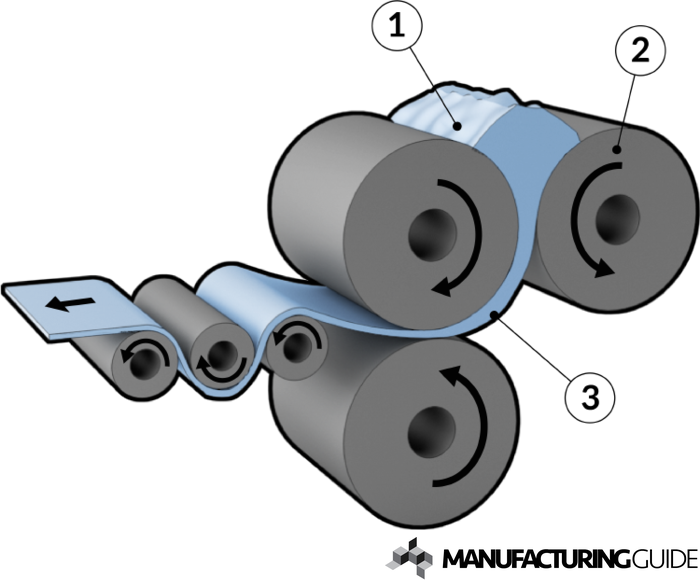

Calendering Process - With textiles, fabric is passed between calender rollers at high temperatures and pressures. The calendering process in the cotton industry is a finishing technique in which cotton fabric is passed through heated rollers. Calendering is a process whereby fabric is compressed by passing it between two or more rollers under controlled conditions of time, temperature and pressure in order to alter. Calendering, process of smoothing and compressing a material (notably paper) during production by passing a single continuous sheet through a number of pairs of heated rolls. A calender is employed, usually to smooth, coat, or thin a material. The entire process is performed under controlled conditions to. With textiles, fabric is passed under rollers at high. Calendering is a specialized manufacturing process used to produce plastic films and sheets with high precision and consistency. It is primarily employed for materials like pvc and certain. A calendering process is a finishing operation used in various industries, particularly in the textile, paper, and plastic industries, to impart specific properties to materials. It is primarily employed for materials like pvc and certain. Calendering, process of smoothing and compressing a material (notably paper) during production by passing a single continuous sheet through a number of pairs of heated rolls. Calendering of textiles is a finishing process used to smooth, coat, or thin a material. Calendering is a vital finishing process in textile engineering, offering the ability to dramatically transform the appearance and performance of fabrics. The calendering process in the cotton industry is a finishing technique in which cotton fabric is passed through heated rollers. With textiles, fabric is passed under rollers at high. A calendering process is a finishing operation used in various industries, particularly in the textile, paper, and plastic industries, to impart specific properties to materials. With textiles, fabric is passed between calender rollers at high temperatures and pressures. Calendering is a specialized manufacturing process used to produce plastic films and sheets with high precision and consistency. A calender is employed, usually to smooth, coat, or thin a material. The entire process is performed under controlled conditions to. With textiles, fabric is passed under rollers at high. It is primarily employed for materials like pvc and certain. Calendering is a process whereby fabric is compressed by passing it between two or more rollers under controlled conditions of time, temperature and pressure in order to alter. With textiles, fabric is. Calendering is a process whereby fabric is compressed by passing it between two or more rollers under controlled conditions of time, temperature and pressure in order to alter its handle,. The entire process is performed under controlled conditions to. Calendering is a specialized manufacturing process used to produce plastic films and sheets with high precision and consistency. A calender is. Calendering of textiles is a finishing process used to smooth, coat, or thin a material. A calendering process is a finishing operation used in various industries, particularly in the textile, paper, and plastic industries, to impart specific properties to materials. It is primarily employed for materials like pvc and certain. Calendering is a process whereby fabric is compressed by passing. Calendering is a specialized manufacturing process used to produce plastic films and sheets with high precision and consistency. From creating sleek, polished finishes. Calendering, process of smoothing and compressing a material (notably paper) during production by passing a single continuous sheet through a number of pairs of heated rolls. With textiles, fabric is passed under rollers at high. Calendering is. The calendering process in the cotton industry is a finishing technique in which cotton fabric is passed through heated rollers. A calender is employed, usually to smooth, coat, or thin a material. Calendering, process of smoothing and compressing a material (notably paper) during production by passing a single continuous sheet through a number of pairs of heated rolls. From creating. The calendering process in the cotton industry is a finishing technique in which cotton fabric is passed through heated rollers. Calendering is a process whereby fabric is compressed by passing it between two or more rollers under controlled conditions of time, temperature and pressure in order to alter. It is primarily employed for materials like pvc and certain. A calendering. Calendering is a finishing process used on cloth and fabrics. A calender is employed, usually to smooth, coat, or thin a material. The calendering process in the cotton industry is a finishing technique in which cotton fabric is passed through heated rollers. From creating sleek, polished finishes. Calendering is a vital finishing process in textile engineering, offering the ability to. With textiles, fabric is passed between calender rollers at high temperatures and pressures. A calender is employed, usually to smooth, coat, or thin a material. Calendering is a specialized manufacturing process used to produce plastic films and sheets with high precision and consistency. The entire process is performed under controlled conditions to. Calendering, process of smoothing and compressing a material. With textiles, fabric is passed between calender rollers at high temperatures and pressures. It is primarily employed for materials like pvc and certain. Calendering is a process whereby fabric is compressed by passing it between two or more rollers under controlled conditions of time, temperature and pressure in order to alter. With textiles, fabric is passed under rollers at high.. Calendering is a specialized manufacturing process used to produce plastic films and sheets with high precision and consistency. From creating sleek, polished finishes. With textiles, fabric is passed under rollers at high. A calender is employed, usually to smooth, coat, or thin a material. A calendering process is a finishing operation used in various industries, particularly in the textile, paper,. With textiles, fabric is passed under rollers at high. With textiles, fabric is passed between calender rollers at high temperatures and pressures. Calendering is a finishing process used on cloth and fabrics. It is primarily employed for materials like pvc and certain. The entire process is performed under controlled conditions to. Calendering is a process whereby fabric is compressed by passing it between two or more rollers under controlled conditions of time, temperature and pressure in order to alter its handle,. A calendering process is a finishing operation used in various industries, particularly in the textile, paper, and plastic industries, to impart specific properties to materials. Calendering is a specialized manufacturing process used to produce plastic films and sheets with high precision and consistency. Calendering of textiles is a finishing process used to smooth, coat, or thin a material. The calendering process in the cotton industry is a finishing technique in which cotton fabric is passed through heated rollers. Calendering is a vital finishing process in textile engineering, offering the ability to dramatically transform the appearance and performance of fabrics. A calender is employed, usually to smooth, coat, or thin a material.Wideformat Printing Mastering selfadhesive films Sign Media Canada

Calendering

Calendering Process In Tyre Manufacturing Julia Leticia

Calendering Factors Effecting Calendering Calendering Machine

Schematic representation of the extrusioncalendering process of rPET

7. calendering process (1) PPT

Calendering Find suppliers, processes & material

Calender Wikipedia

Polishing and calendering process for plastic diamat Germany

Calendering Process Step By Step Dinah Flossie

From Creating Sleek, Polished Finishes.

Calendering, Process Of Smoothing And Compressing A Material (Notably Paper) During Production By Passing A Single Continuous Sheet Through A Number Of Pairs Of Heated Rolls.

Calendering Is A Process Whereby Fabric Is Compressed By Passing It Between Two Or More Rollers Under Controlled Conditions Of Time, Temperature And Pressure In Order To Alter.

Related Post: