Calendering Rubber

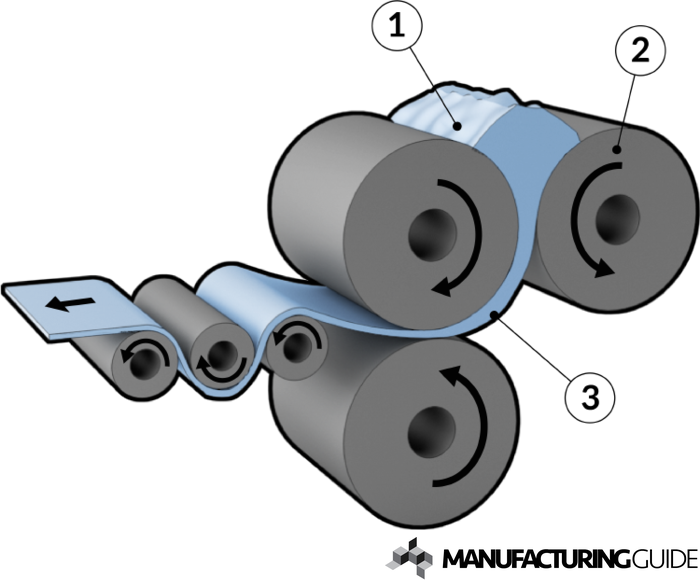

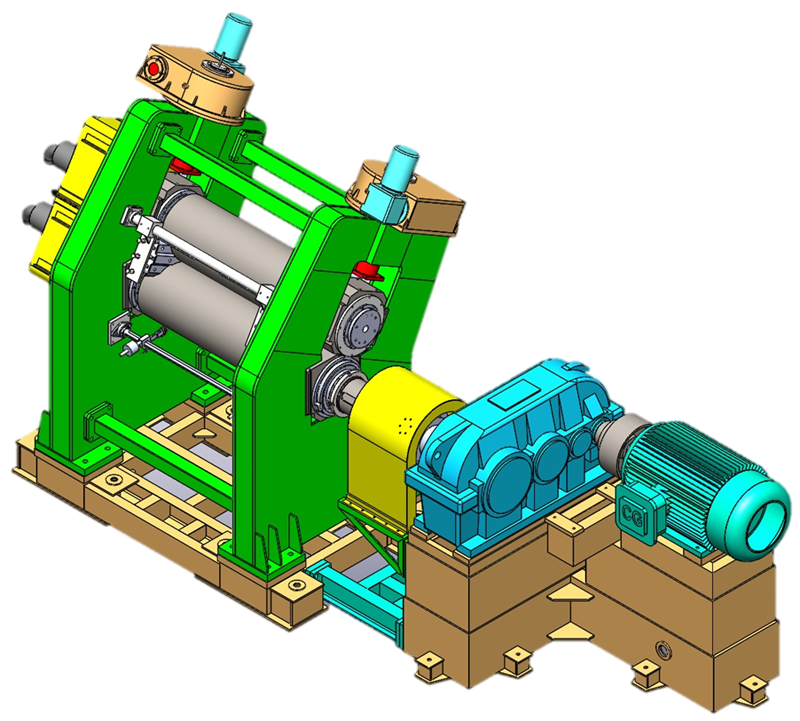

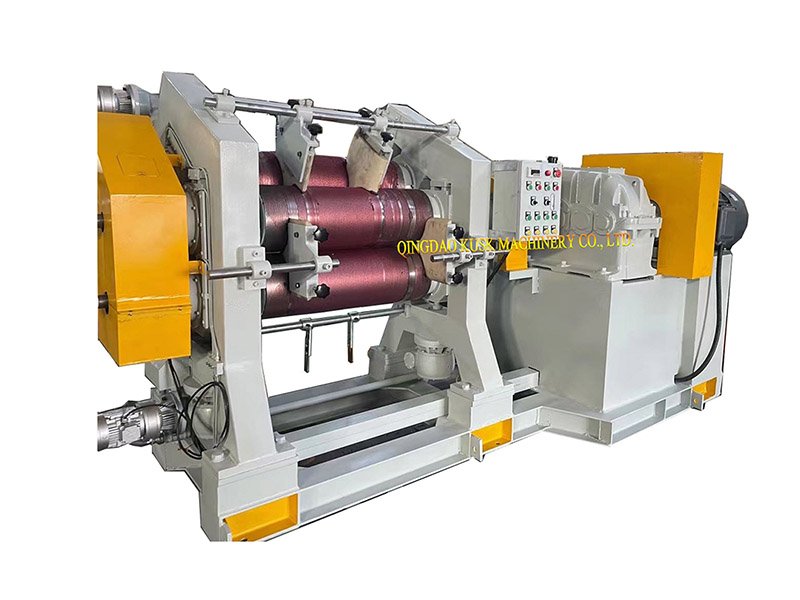

Calendering Rubber - Rebuilding capabilities include barrel relining, incorporating new screw designs, & upgrading. Calendering is an important process in the production of rubber products, particularly belts in which an inner fabric layer is used. It involves passing rubber through a series of rollers. We specialize in the art of rubber. What are the factors that affect the compression speed of the rubber calender? More than one shaping technique may be used,. It also ties to controlling production costs and using materials effectively. Your guiding principle for calender line operation should be consistency and continuity. This is a mechanical process by which rubber is pressed into textiles (cloth, fabric, tire cord) forming. The following will introduce you the calendering process of the rubber calender. The layers of sheets that have been calendered can be. The following will introduce you the calendering process of the rubber calender. Calendering is one of the oldest rubber processing technologies. This is a mechanical process by which rubber is pressed into textiles (cloth, fabric, tire cord) forming. Rebuilding capabilities include barrel relining, incorporating new screw designs, & upgrading. Your guiding principle for calender line operation should be consistency and continuity. What are the factors that affect the compression speed of the rubber calender? Calendering is an important process in the production of rubber products, particularly belts in which an inner fabric layer is used. We specialize in the art of rubber. It involves passing rubber through a series of rollers. The following will introduce you the calendering process of the rubber calender. Your guiding principle for calender line operation should be consistency and continuity. We specialize in the art of rubber. The layers of sheets that have been calendered can be. The choice of rubber calender affects product quality and productivity. More than one shaping technique may be used,. Shaping rubber products occurs using four general techniques: The choice of rubber calender affects product quality and productivity. What are the factors that affect the compression speed of the rubber calender? The following will introduce you the calendering process of the rubber calender. More than one shaping technique may be used,. The choice of rubber calender affects product quality and productivity. This is a mechanical process by which rubber is pressed into textiles (cloth, fabric, tire cord) forming. Here is the content list: Extrusion, calendering, coating or molding, and casting. Calendering is one of the oldest rubber processing technologies. Your guiding principle for calender line operation should be consistency and continuity. Rubber calendering is classified into two based on what you are calendering. Manufacturer of new & rebuilt plastics calendering & rubber calendering machinery. More than one shaping technique may be used,. Manufacturer of new & rebuilt plastics calendering & rubber calendering machinery. It also ties to controlling production costs and using materials effectively. The layers of sheets that have been calendered can be. Here is the content list: Rebuilding capabilities include barrel relining, incorporating new screw designs, & upgrading. The following will introduce you the calendering process of the rubber calender. Rubber calendering is classified into two based on what you are calendering. Calendering is one of the oldest rubber processing technologies. Extrusion, calendering, coating or molding, and casting. The layers of sheets that have been calendered can be. It involves passing rubber through a series of rollers. It also ties to controlling production costs and using materials effectively. The choice of rubber calender affects product quality and productivity. Extrusion, calendering, coating or molding, and casting. We specialize in the art of rubber. Calendering is an important process in the production of rubber products, particularly belts in which an inner fabric layer is used. Understanding the different types of rubber calenders is critical to achieving efficient rubber processing. More than one shaping technique may be used,. Rubber calendering is classified into two based on what you are calendering. Shaping rubber products occurs using. This is a mechanical process by which rubber is pressed into textiles (cloth, fabric, tire cord) forming. Rebuilding capabilities include barrel relining, incorporating new screw designs, & upgrading. Manufacturer of new & rebuilt plastics calendering & rubber calendering machinery. What are the factors that affect the compression speed of the rubber calender? Shaping rubber products occurs using four general techniques: Calendering is one of the oldest rubber processing technologies. It involves passing rubber through a series of rollers. Here is the content list: What are the factors that affect the compression speed of the rubber calender? Your guiding principle for calender line operation should be consistency and continuity. Calendering is an important process in the production of rubber products, particularly belts in which an inner fabric layer is used. The layers of sheets that have been calendered can be. What are the factors that affect the compression speed of the rubber calender? Here is the content list: Manufacturer of new & rebuilt plastics calendering & rubber calendering machinery. Extrusion, calendering, coating or molding, and casting. More than one shaping technique may be used,. Understanding the different types of rubber calenders is critical to achieving efficient rubber processing. Rebuilding capabilities include barrel relining, incorporating new screw designs, & upgrading. The choice of rubber calender affects product quality and productivity. Shaping rubber products occurs using four general techniques: We specialize in the art of rubber. It also ties to controlling production costs and using materials effectively. This is a mechanical process by which rubber is pressed into textiles (cloth, fabric, tire cord) forming. The following will introduce you the calendering process of the rubber calender.Calendering Process For Rubber Viv Lilith

Custom Rubber Calendering Landing Goodyear Rubber

Custom Rubber Calendering Dyanne Lyndsey

Rubber Calender Rubber Calendering Line

4 Roll PVC/Rubber Calender Machine Calendering Mill Xy4 400 X 1200

Rubber Calendering Machine Home

Passaic Rubber Company Calendering Rubber YouTube

Rubber Calendering Process Goodyear Rubber

The Science Of Rubber Calendering Lindas

Rubber Calender Rubber Calendering Line

Rubber Calendering Is Classified Into Two Based On What You Are Calendering.

It Involves Passing Rubber Through A Series Of Rollers.

Your Guiding Principle For Calender Line Operation Should Be Consistency And Continuity.

Calendering Is One Of The Oldest Rubber Processing Technologies.

Related Post: